Water is a vital resource, indispensable for our health, hygiene, and societal growth. Potable water tanks serve an integral role in the storage and supply of clean, safe water for everyday needs. Yet, these tanks can encounter issues requiring efficient waterproofing solutions. IMC/Nukote Canada presents an innovative answer: polyurea protective coatings.

Potable Water Tanks: An Overview

Potable water tanks are systems designed to store water fit for human consumption. These tanks, found in homes, schools, hospitals, hotels, offices and beyond, are vital for a consistent supply of clean water, particularly in areas where water provision can be sporadic.

Waterproofing is crucial for potable water tanks, without which, tanks can develop leaks, leading to water loss and potential contamination. Waterproofing also safeguards the tank material, be it concrete, steel, or fiberglass, from water damage, extending the tank’s lifespan and reducing long-term exposure.

Polyurea Protective Coatings: A High-Performance Waterproofing Solution

Polyurea protective coatings are a potent solution for waterproofing potable water tanks. This high-performance Waterproof Coating forms a seamless, waterproof membrane, effectively sealing all cracks and fissures, preventing water leakage.

Polyurea coatings are also resistant to chemicals and abrasion, ideal for harsh environments. Furthermore, their quick application and rapid curing time minimizes downtime, promoting a quicker return to service than traditional waterproofing methods.

The Significance of ANSI NSF 61 Certification

For potable water tanks, safety is paramount. Products used within these systems, such as polyurea protective coatings, should be ANSI NSF 61 certified. This certification verifies the product’s safety for use in contact with drinking water, providing assurance of quality and safety for consumers.

The process to obtain ANSI NSF 61 certification involves rigorous testing for a wide range of potential contaminants. This ensures both short-term and long-term safety of the water supply. Thus, a product with ANSI NSF 61 certification complies with the highest recognized health effects standard for water-related products in North America.

Spotlight on Nukote ST PW

Nukote ST PW is a specifically modified pure aromatic polyurea designed for coating substrates used for the storage and transmission of potable and drinking water. Its ANSI/NSF 61 compliance and approval make it a trustworthy choice for potable water tank waterproofing.

Nukote ST PW also resists numerous solvents, acids, and alkalis, maintaining high physical properties upon weathering. This fast-set, 100% solids product is suitable for a variety of substrates like concrete and steel as a waterproofing membrane, anti-corrosion, and abrasion-resistant liner. For water infrastructure not transporting potable water, like culverts where the waterproof coating is exposed to the natural environment such as streams, the ANSI/NSF 61 certification provides reassurance that any surrounding wild life will be safe.

Case Studies: Polyurea Waterproofing Protective Coatings in Action

Case Study: Goulais Mission, Sault Ste. Marie, ON

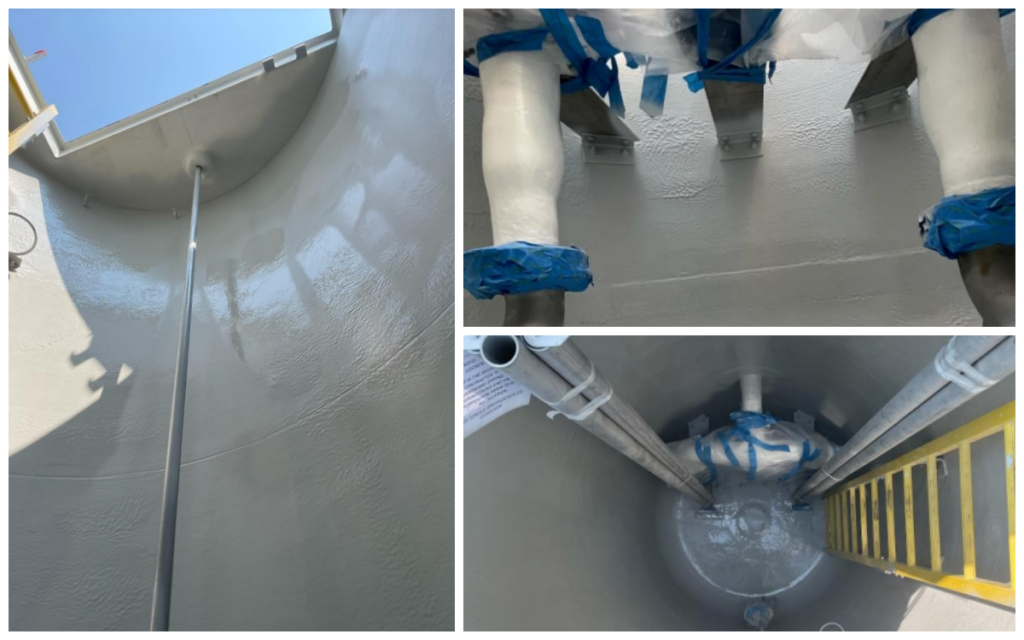

This project in Sault Ste. Marie, ON underscored the role of polyurea protective coatings in potable water tank protection. The project took place at Goulais Mission, where a concrete and a fiberglass potable water tank needed waterproofing. After the necessary preparation, the concrete tank was coated with NUKOTE EP Prime II, while the fiberglass tank was sanded and solvent wiped. Following this, the Nukote ST PW polyurea waterproof and protective membrane was applied using a plural component spray system. The result was a fully waterproofed and safeguarded potable water tank, showcasing the effectiveness of the polyurea protective coating.

Case Study: Hiawatha First Nation, Hiawatha Reserve

A similar project at Hiawatha First Nation Reserve reiterated the success of polyurea protective coatings. This project involved applying a protective polyurea coating to an underground potable water tank at a daycare center. Given the location’s use, the project was subject to strict regulatory requirements. Similar to the Goulais Mission project, the tank was prepped, cleaned, and coated with NUKOTE EP Prime II and Nukote ST PW. The project’s successful completion further emphasized the utility and efficiency of polyurea protective coatings for waterproofing potable water tanks. Learn more about the case study here.

Your Next Step to Safe and Durable Water Tanks – Choose IMC/Nukote Canada

Ensure the longevity and safety of your potable water tanks with Nukote ST PW‘s reliable and certified polyurea protective coating. Witnessed in action, this coating has proven effective in maintaining the structural integrity of tanks while securing water supply. For a robust waterproofing solution, contact IMC/Nukote Canada today and prioritize quality, health, and durability.

Karli Logan is the Owner and President of IMC Distributors which is the exclusive partner of Nukote Coating Systems in Canada. With a B.Sc and M.Sc, as well as a demonstrated history of working across a number of industries, she has a passion to drive significant gains and benefits for IMC’s clients.

Karli Logan is the Owner and President of IMC Distributors which is the exclusive partner of Nukote Coating Systems in Canada. With a B.Sc and M.Sc, as well as a demonstrated history of working across a number of industries, she has a passion to drive significant gains and benefits for IMC’s clients.